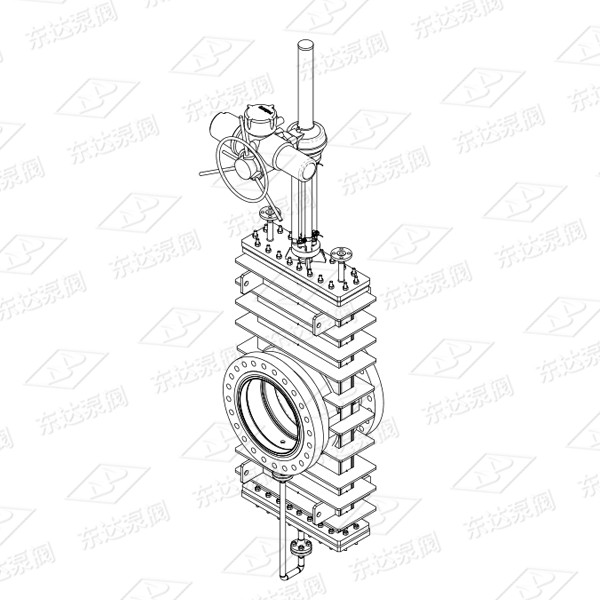

product description:

Lightweight flat gate valve (single gate without orifice, with orifice, the original model is SZ47)

SZ43WPF, SZ43WPD, SZ43WPY, SZ43PF, SZ43PD, SZ43PY, SZ543WPF, SZ543WPD, SZ543WPY

SZ543PF, SZ543PD, SZ543PY, SZ9B43WPF, SZ9B43WPD, SZ9B43PY, SZ9B43PF, SZ9B43PD, SZ9B43PYS

Add "K" before the anti-sulfur valve model, add "L" before the regulating valve model, add "M" after the wear-resistant F

Specification: 2"-28" in, DN50-700mm

Pressure: 150-900, PN1.0-6.4MPa

The light-duty flat gate valve is suitable for Class150~900/PN1.0~16.0MPa, working temperature -29~150℃ in port terminal oil storage and transportation projects or airport oil depots and other facilities. It is used to cut off or connect the medium in the pipeline. To cut off and adjust the pipeline media;

Application range:

The flat gate valve is suitable for natural gas, petroleum, chemical, environmental protection, urban pipelines, gas pipelines and other transportation pipelines, venting systems and steam storage devices, as opening and closing equipment.

1. For oil and natural gas pipelines, use single or double gate flat gate valves. If you need to clean the pipeline, use single or double gate open-rod flat gate valve with diversion holes.

(Z43F/Z44H)

2. For the transportation pipeline and storage and transportation equipment of refined oil, select single gate valve without diversion hole or light flat gate valve.

(Z43WBF/Z43WPF)

3. For oil and natural gas extraction wellhead devices, single-gate or double-gate flat gate valves with dark rod floating valve seats and diversion holes are used, most of which are API16A standards, and the pressure levels are API2000, API3000, API5000, API10000, API15000, API20000.

(2 1/16”- 7 1/16” 2000-20000 PSI PR1. PR2 PSL1-PSL4 AA. BB. CC. DD. EE. FF)

4. For pipelines with suspended particles, use hard-sealed flat gate valves or knife-type flat gate valves.

(Z43HF/PZ73H)

5. The city gas transmission pipeline uses a flat gate valve dedicated to buried gas with a dark rod.

(Z47F/RQMZ67F)

6. For urban tap water projects, single-gate soft-sealed open-rod flat gate valve is selected.

(Z43WBF)

Structural features:

1. Using floating valve seat, two-way opening and closing, reliable sealing, flexible opening and closing.

2. The ram has a guide bar for precise guidance, and the sealing surface is spray-welded with cemented carbide, which is resistant to erosion.

3. The valve body has a high load-bearing capacity, and the passage is straight-through. When fully opened, it is similar to a straight pipe through the gate orifice, and the flow resistance is small. The valve stem adopts composite packing and multiple seals, making the seal reliable and low friction.

4. When closing the valve, turn the handwheel clockwise, and the gate moves down to the bottom. Due to the pressure of the medium, the inlet end seal seat is pushed toward the gate to form a larger seal specific pressure, thus forming the first seal . At the same time, the gate is pressed against the seal seat at the outlet end to form a double seal.

5. Due to the double seal, the wearing parts can be replaced without affecting the pipeline work. This is an important feature that our products have priority over similar products at home and abroad.

6. When opening the gate, turn the handwheel counterclockwise to move the gate, and the diversion hole and the passage hole are connected. As the ram rises, the through hole gradually increases. When it reaches the limit position, the diversion hole and the channel hole overlap, and then it is fully opened.

Standard Specification:

Design and manufacturing standards: API 6D GB/T 19672

Structure length standard: API 6D GB/T 12221

Connecting flange standard: ASME B16.5 HG/T 20592

Pressure and temperature rating: ASME B16.34 GB/T 12224

Test inspection standard: API598 GB/T 13927

product advantages:

The flow resistance is small, and its flow resistance without shrinking is similar to that of a short tube. The flat gate valve with diversion hole can be directly used for pigging when installed on the pipeline. Since the gate slides on the two valve seat surfaces, the flat gate valve fluid can be applied to the medium with suspended particles, and the sealing surface of the flat gate valve is actually automatically positioned. The seat sealing surface will not be damaged by thermal deformation of the valve body. Moreover, even if the valve is closed in a cold state, the thermal elongation of the valve stem will not overload the sealing surface. At the same time, when the valve is closed, the flat gate valve without diversion hole does not require the closing position of the gate to have a higher accuracy, so the electric flat valve can control the opening and closing position by the stroke.

Parts materials and working conditions:

Part Name | Parts materials |

GB/T 19672 | API 6D |

Valve/bonnet | WCB | Q345B | A216 WCB | A516 GR50 |

gate | 16Mn+ENP | 16Mn+ENP | A182 F304+STL | A516 GR50+ENP |

Stem | 2Cr13 | 2Cr13 | A182 F304 | A182 F6A |

Valve seat | 25#+RPTFE | 25#+RPTFE | A182 F304+STL | A516 GR50+RPTFE |

filler | Flexible graphite PTFE/VITON |

Gasket | Flexible graphite/304 |

bolt | 35 | 35CrMo | A193-B7M | A193 B7 |

proper temperature | -29~150℃ | -29~150℃ | -29~150℃ | -29~150℃ |

Applicable medium | Crude oil refined oil | Crude oil refined oil | Crude oil refined oil | Crude oil refined oil |

0577-67961597 / 13806834846

0577-67961597 / 13806834846 0577-67961597 / 13806834846

0577-67961597 / 13806834846

浙公网安备 33032402002076号网站统计

浙公网安备 33032402002076号网站统计